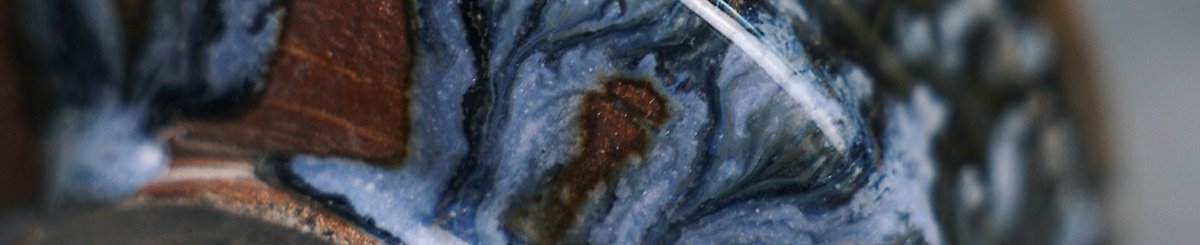

[flow glaze]

When the ceramic glaze and the glass melt at high temperature, the flow characteristics are very different. When the glaze is melted in the kiln, it must maintain a certain viscosity. Otherwise, it will flow down the blank, and flow to the bottom to stick the pottery and the refractory shed. This work is not available.

For ceramic artists, in the formation of glaze formula, in addition to considering its viscosity and the temperature inside the kiln (heating and cooling), the expansion coefficient of the glaze and the embryo body should be matched, so that it will not be cooled after firing. In the process, because the shrinkage of the embryo body and the glaze layer is inconsistent, glaze or cracking occurs.

https://farm1.staticflickr.com/936/42873610364_39cc7c1933_b.jpg

**Firewood introduction**

"Chai burning" is a traditional method of burning kiln, which burns wood to a high temperature of 1200 degrees or more.

There is a "fire mark" left by the firewood directly in the blank, and the ash that naturally falls after the firewood burns, making the work warm and rich in color, which is the realm that electric kiln and gas kiln cannot reach.

Compared with the general electric kiln and gas kiln, it takes about 8~10 days for the wood to burn from the kiln, the ignition to the kiln, and then the temperature.

Coupled with the large kiln pressure of the wood burning, as well as the humidity of the climate, the degree of dryness of the wood, the speed of the artificial wood, the location of the kiln, etc., may lead to the success or failure of the work, and the damage rate is also high.

Old-fashioned firewood writers will consider the speed of the whole kiln airflow when arranging the kiln. How to discharge from different sizes of the works, how to estimate how the fire road rises, how to cast firewood, and how to burn the fire mind. Every process must be focused on, so that the perfect wood-burning works are presented.

Manufacturing location: Hualien, Taiwan

https://farm1.staticflickr.com/917/43544255812_f01211ed14_b.jpg

**Precautions**

1. The works are handmade, the texture and color are not the same, and the computer display is different.

2. The surface of the work has irregularities, traces of bubbles, glaze, and crack texture.

3. The works are all real shots. If you have any questions, please feel free to contact us. We will reply you as soon as possible!!

Product Description

Product Details

- Material

- Pottery

- How It's Made

- Handmade

- Where It's Made

- Taiwan

- Popularity

-

- 1,329 views

- 1 sold

- 2 have saved this item

- Product Type

- Original Design

- Listing Summary

- Size: height 9.5x diameter 10x length 14.5 (including handle) cm; hand-drawing / gray-blue glaze / firewood

Shipping Fees and More

- Shipping

- Payment method

-

- Credit/debit card payment

- Alipay

- Refunds & Exchanges

- Read more about refunds and exchanges

- Report

- Report this item