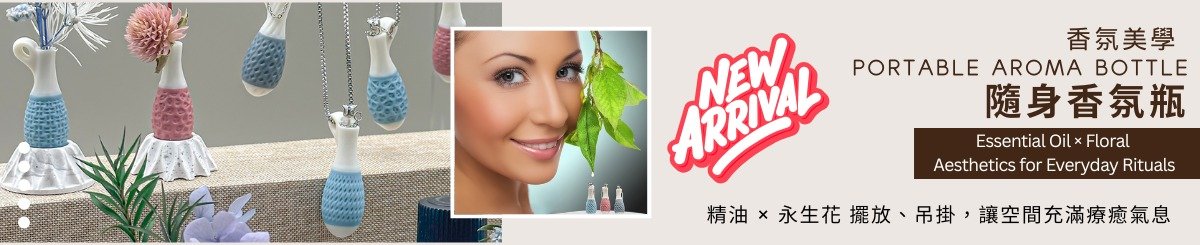

This is more than just a mini vase—it's a portable aroma bottle. Combining ceramic craftsmanship with a fragrant experience, it lets you enjoy soothing scents anytime in your daily life. For more details, please visit the product page.

- Items26

- Shop Story

- Refund & Exchange Policy

Featured Products

- Accessories(22)

- Stationery(1)

- Home & Living(3)

Click on the search bar to search for listings in this shop!

26 listings

「TMEI」began with Professor Tang's love for ceramics and groundbreaking 3D printing technology. Together with his artistic wife, Mei, they explored ceramics' potential. Tang and his son's invention of a 3D ceramic printer led to 「TMEI」

They applied this innovation to create exquisite jewelry, blending tradition with modernity. 「TMEI」 aspires to redefine ceramic jewelry as elegant, fashionable art, reflecting their passion for quality and artistry.

「TMEI」 combines ceramic art and modern technology to create unique and exquisite jewelry, allowing wearers to feel the charm of beauty and the power of art. Their goal is to redefine ceramic jewelry and turn it into an elegant and fashionable work of art, showing the charm of this ancient craft to the world. At "TMEI", they respect tradition, pursue innovation, focus on quality, and are committed to the perfect presentation of every work.

Experience the artistry of 「TMEI」with us.

Our Technology

「TMEI」 is a ceramic jewelry brand created using an exclusive 3D printing technology, pushing the boundaries of design to unprecedented levels and breaking the constraints of handcrafting to create unique designs.

★ 1. Accurate 3D Design and Model Calibration ★

When designing ceramic products, it is necessary to consider the shrinkage phenomenon during the firing process. To ensure that the final product dimensions meet expectations, we use digital 3D software to enlarge the dimensions of three views by 10-15% depending on the material and axis. We conduct multiple experiments to ensure the accuracy of this ratio.

When designers are modeling, errors such as broken surfaces, incorrect surface directions, or non-manifold edges in the model may cause errors in slicing software. If the printing results are unsatisfactory, it may be due to defects in the 3D model, requiring a return to the modeling software for inspection and file correction to ensure the model is fully closed. Our experienced and patient staff meticulously inspect the details of the 3D model, repairing various defects to ensure the final production of an accurate 3D model.

★ 2. Exclusive Slurry Method for Crafting High-Density Ceramic Products ★

At present, there are not many international 3D printers that use ceramic materials. Our process differs from conventional ceramic 3D printing primarily in our use of slurry, whereas most other methods utilize dry powders. This distinction brings many advantages, such as the ability to uniformly lay down extremely fine ceramic particles, ensuring the final product is dense and flawless.

We sieve various ceramic powders ranging from 0.5 to 45 micrometers in diameter, mixing them with water and binders. After undergoing prolonged ball milling, dispersion, vacuum deaeration, and other processes, we produce slurry with excellent fluidity, suspension, and stability. This high-quality slurry flows into the feed system of the 3D printer, forming layers of thin films. The thickness of these films can be adjusted according to requirements, ranging from 20 to 50 micrometers per layer. The resulting products are sturdy, with smooth and flawless surfaces.

★ 3. High-Resolution Printing Technology ★

To manufacture exquisite products, we utilize printing heads capable of jetting high-performance adhesives with high resolution. These printing heads employ microelectromechanical systems (MEMS) and thin film technology to increase nozzle density, reduce nozzle size, and produce fine droplets. Currently, our nozzle size is smaller than the diameter of a human hair.

We have designed a cleaning system that includes a cleaning fluid pump, along with developing an inkjet monitoring system and an automatic nozzle cleaning procedure. The monitoring system can promptly monitor print quality, and when the print quality deteriorates, it activates the cleaning fluid pump for cleaning to ensure the inkjet system operates normally. These are measures we must take to maintain product quality.

Product features

【1. Delicate Lines, Unique Designs】

Our designs integrate natural flowing lines, unique perforations, and intricate textures that can only be achieved through 3D printing. Each design exudes artistry and dynamism, imbuing our ceramic ornaments with vitality and uniqueness, allowing you to feel confident and noticed when wearing them.

【2. Eco-conscious Natural Material】

We utilize ceramic, a natural material, to make our jewelry, fully harnessing its eco-friendly characteristics. Ceramic originates from nature and does not harm the environment.

《Ceramic Material》

Early ceramic materials refer to traditional products made from clay mixed with finely ground natural minerals, kneaded, shaped, and fired, such as pottery, tiles, and ceramics. Scientific advancements have led to advanced ceramics like oxide, metal, and piezoelectric ceramics, used in high-tech aerospace, medical, and communication equipment. Porcelain clay, known for its purity and plasticity, is ideal for high-quality porcelain, ceramic artworks, and electronic components.

【3. Encounter Nature's Colors】

「TMEI」 ceramic necklaces blend the colors of nature in Chinese literature, paying tribute to the poetic beauty of nature. From the deep greens and bright yellows of landscapes to the light pinks and soft blues of spring, the necklace captures the essence of nature, allowing you to constantly feel the beauty of the natural world.

- Customized products

- Opened personal hygiene products

- Once the designer receives a request, they will contact the customer within 2 working days.

- Once the designer approves the refund, please return the refund item(s) within 3 working days and send a message to the designer via Chats to notify them. Please also attach the name of the courier and the tracking number.

- Once the designer receives the refund item(s), they will verify and complete the refund within 1 working days.

- If you have any questions about the item or order, please contact the designer via Chats.